Banners - advertising tarpaulins, car tarpaulins

Print delivery time within 3 days. We ship within 24 hours!

- We print advertising tarpaulins in roll widths up to 500cm in one piece.

- We print in interior and exterior quality and with UV ink.

- For advertising tarpaulins we use cast banners, for long-term applications and laminated, eco-common materials for shorter-term use.

CAR WRAPS BRNO, PRINTING AND PRODUCTION OF CAR WRAPS

We print on special materials for the production of car wraps for the manufacturers of car wraps from the Czech Republic.

- We print car coats with solvent inks and UV inks on a DURST Rho 320r machine.

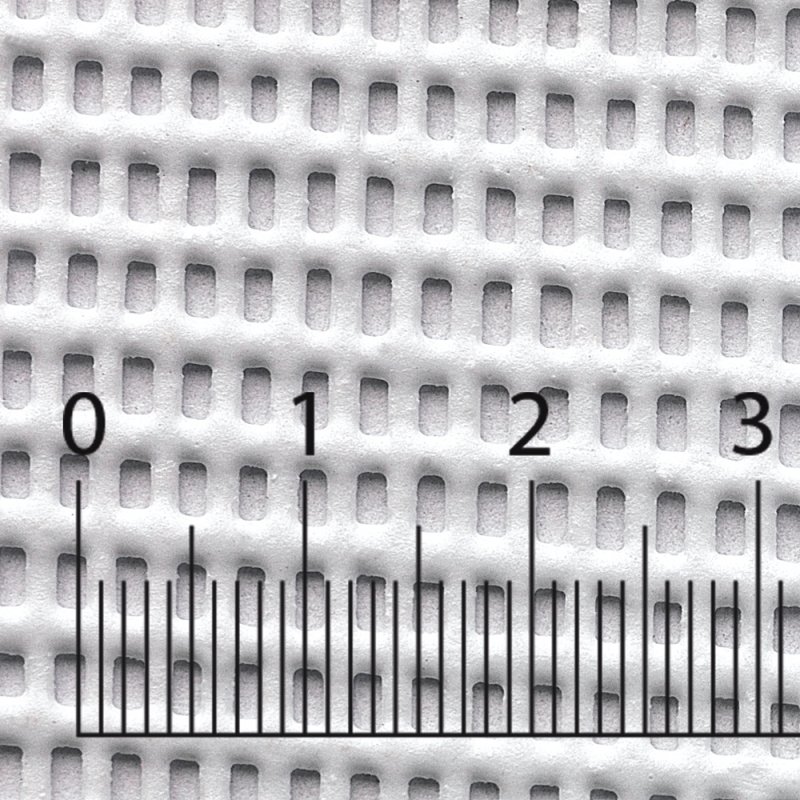

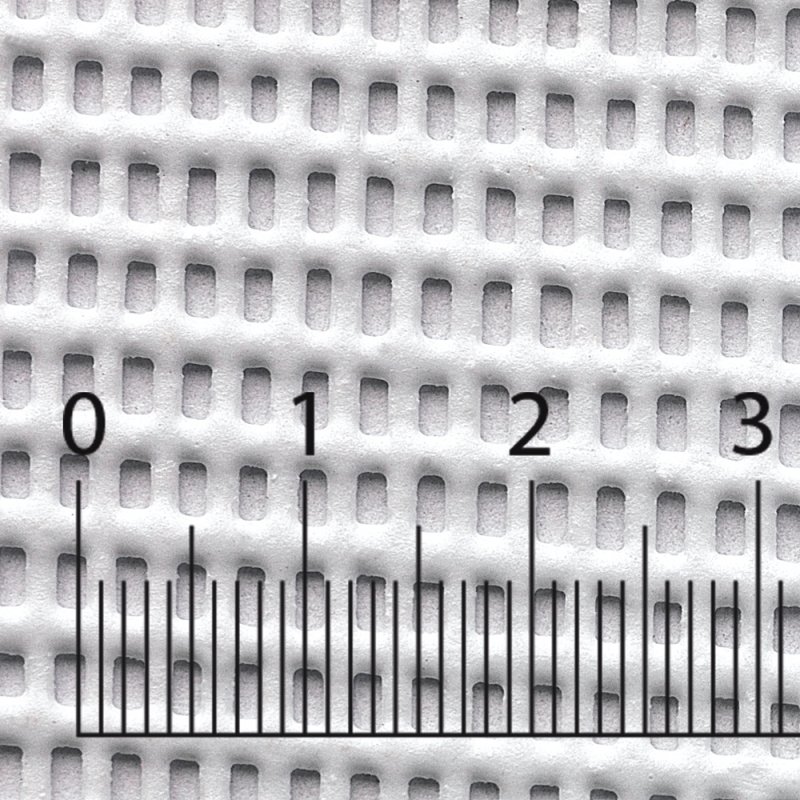

- we print on vinyl tarpaulins of 650 and 900 g/m2 from Mehler and Endutex

- we protect the sails with liquid lamination - the sails have high mechanical resistance and colour fastness up to 5 years

- we also provide special liquid lamination of sails printed with UV ink.

Are you interested in car covers or their printing? Contact us >>>>.

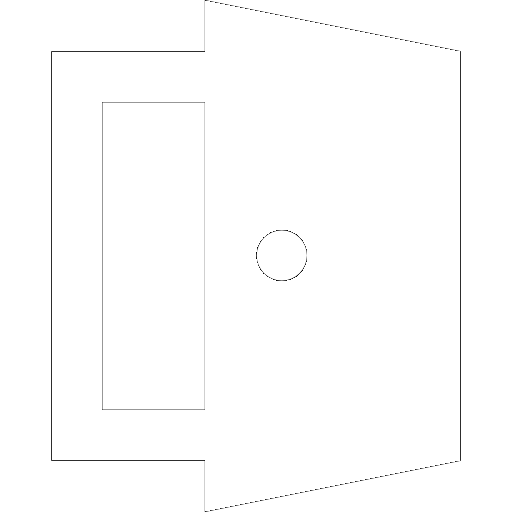

reinforced edge with eye plastic HF weld face

reinforced edge with eye plastic HF weld face